#1 App for easy manufacturing

Production planning, process management, and product development – all in one system.

Request a Demo

Complete Manufacturing Solution

Everything you need to manage your production operations

Bill of Materials (BoM)

Multi-Level Product Structures

• Create unlimited levels of BoM for complex products

• Support for variants and configurable products

• Component substitution and alternative materials

• BoM versioning and revision control

• Cost calculation based on components

• Automatic BoM explosion for nested structures

Manufacturing Orders

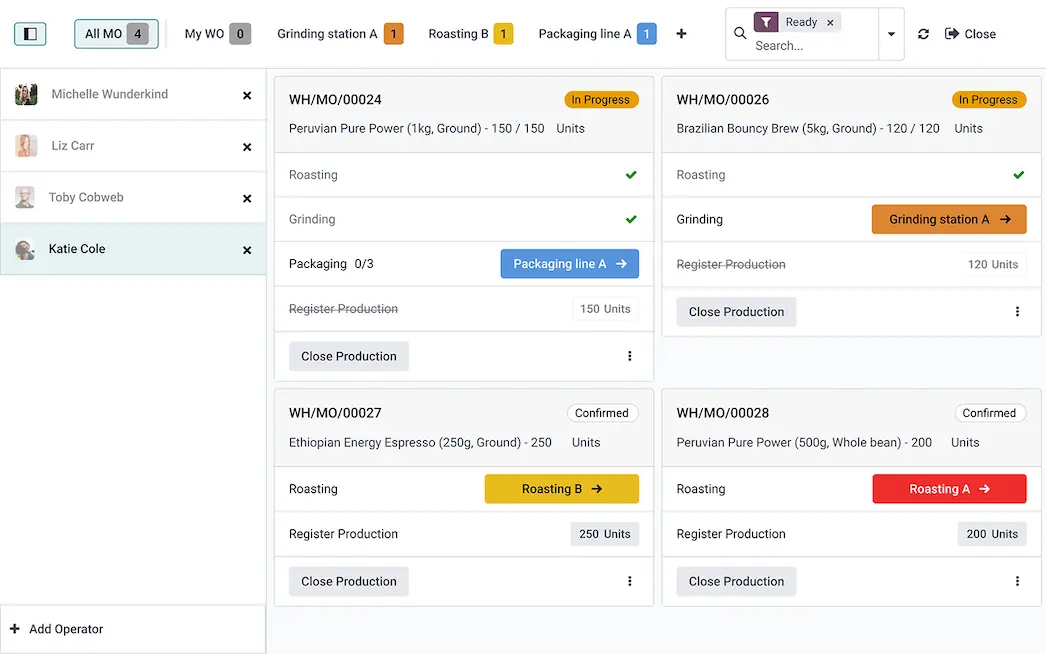

Production Order Management

• Create manufacturing orders from sales or forecasts

• Real-time production tracking and progress monitoring

• Work order generation with step-by-step instructions

• Material availability checking before production

• Automatic backorder creation for missing components

• Production reporting and analytics

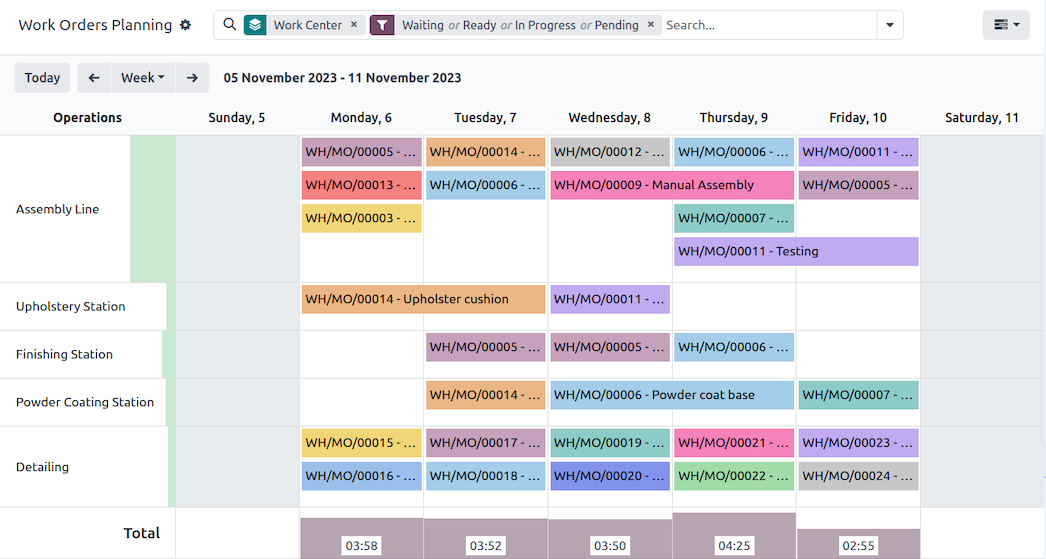

Work Centers & Routing

Optimize Production Flow

• Define work centers with capacity and efficiency

• Create routing sequences for production steps

• Time tracking per operation and work center

• Work center utilization and OEE monitoring

• Maintenance scheduling integration

• Bottleneck identification and analysis

Quality Control

Built-in Quality Management

• Quality control points at any production stage

• Automated quality checks and inspections

• Non-conformity tracking and alerts

• Quality certificates and documentation

• Statistical process control (SPC)

• Traceability with lot and serial numbers

Stay ahead of your schedule

with smart planning

Plan production orders and manage resources efficiently.

Fine-tune planning easily with Gantt charts.

Advanced Manufacturing

Features

Product Lifecycle Management (PLM)

Manage product versions, engineering change orders (ECO), and design revisions. Track changes throughout the product lifecycle

Maintenance Management

Schedule preventive maintenance, track equipment downtime, and manage maintenance requests to keep production running smoothly

Subcontracting

Manage subcontracted operations, send components to subcontractors, and track external production processes

By-Products & Scrap

Handle by-products from production, track scrap materials, and manage waste efficiently

Batch & Serial Tracking

Full traceability with lot and serial numbers. Track materials from the supplier to the finished product

Master Production Schedule (MPS)

Plan production based on demand forecasts. Balance supply and demand with intelligent scheduling

Tablet/Mobile Interface

Shop floor operators can use tablets to view work orders, report progress, and perform quality checks

Barcode Scanning

Scan components, work orders, and finished products for faster data entry and fewer errors

Integration Ready

Seamlessly integrate with Inventory, Purchase, Sales, and Accounting modules for end-to-end visibility

Why Choose Odoo

Manufacturing?

Reduce Production Costs

Optimize material usage, reduce waste, and improve work center efficiency. Real-time cost tracking helps identify savings opportunities

Improve On-Time Delivery

Smart scheduling ensures production meets customer deadlines. Automatic alerts for delays and bottlenecks keep you proactive

Enhance Product Quality

Built-in quality controls at every stage prevent defects. Traceability ensures quick resolution of quality issues

Scale Your Operations

From small workshops to large factories, Odoo MRP scales with your business. Add work centers and products as you grow